As the name suggests there are many companies which specialize in making wound care products; there is a surprising range of products available. This range is slowly increasing as advances in surgical techniques demand more and more advanced wound dressing solutions. The wound care products generally need to be manufactured inside a clean room where the manufacturing environment can be strictly controlled. This is to reduce the risk of contamination in the products which would be transferred to patients and potentially result in infection. An infection can be detrimental to a patient’s recovery or it can cause serious complications.

Most of the main manufacturers of these products have been established for a long period of time and have developed strong relationships with suppliers of medical grade foams and other, similar materials. This does make it difficult for any new company to enter the market; this is not aided by the fact that the equipment needed to manufacturer these products is not cheap. Alongside this, setting up a clean room is not a task to be undertaken lightly.

Every company which does engage in wound care manufacturing also needs to be ISO accredited and this can be a difficult certification to gain. Various, well established business, such as Baril Corporation and UFP Technologies have gained these certificates and manufacture the following products:

Negative Pressure Dressings

This dressing is designed to create a vacuum which encourages severe wounds to heal and is very good at helping first and second degree burns to heal.

Silicone Dressings

These dressings are often used to treat severe wounds as they can be removed without causing any trauma to the wound – this is thanks to the soft silicone coating on the dressing.

Hydrogel Sheet Dressings

This is similar to the silicone dressing in that it can be used in severe wounds and will not harm the wound when removed. It involves applying gel to the wound and then placing a fine mesh over the top; promoting moisture in the wound to assist healing.

Absorptive Dressings

These are used when a wound is weeping; the dressing is designed to absorb any liquid emanating from the wound.

Hydrocolloid Dressings

These dressings contain gel forming agents and once applied the dressing is waterproof although the longer it stays on the wound the less waterproof it becomes. This type of dressing can be put onto wet wounds as well as dry, making it very versatile.

IV Site Care

This is a transparent dressing which goes over the site of an IV drip. It allows medical professions to monitor the area to ensure there are no complications.

Adhesive Bordered Foam Dressings

The foam dressing is suitably for the majority of wounds, it can be quickly and easily applied using the adhesive border. Foam is very good at absorbing any liquid coming from the wound.

Podiatric Care Devices

There are a variety of medical devices which assist in the treatment of foot, ankle or lower body disorders and these devices are all manufactured in a clean room.

Compression Dressings

A compression dressing is designed to cover a larger area on the body and its main role is to provide support to the patient. The dressing should compress a wound or sprain to ensure it does not come under undue pressure.

Ostomy Care

The ostomy bag is worn above your belt line to collect stools directly from the body. It can be a temporary measure or it can be permanent. The bag has to be manufactured to extremely high specifications to ensure it does the job properly.

Antimicrobial Dressings

These dressings are designed with a layer of anti-microbes which goes against the wound to inhibit the growth of any potentially harmful micro organisms. They are easy to use and have less risk of microbial resistance than many creams.

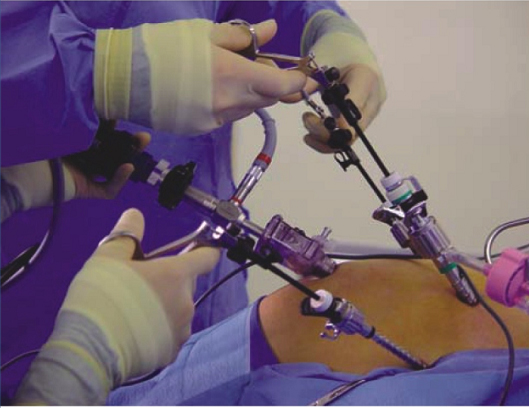

Wound Closure Devices

There are many different types of surface in the human body which need to heal after surgery or similar. Each surface requires a different type of closure device. Organs and skin are the usual places for stitches although there are different types of stitches. These need to be manufactured in a strictly controlled environment.

Topical Analgesic Patches

These patches are used on small areas of the skin and contain medication for pain relief. There are two main types of patches, one which is to prevent irritation and one which is to provide immediate pain relief to an affected area.

Multi Layer Suture Strips

These are strips which are applied to join the skin together, usually after surgery. The sutures will be covered with a sterile dressing and then a compression dressing to support and limit movement of the wound. This will aid healing. The multi layer part of the name refers to the fact that there are several layers of dressing involved in this type of wound.

Surgical Patches

This is the name for a mesh product which supports organs or tissues during surgery. A patch can be temporary which means it will dissolve within a few years or if can be permanent; meaning it will always be a part of the body. As this will be left inside the body it is essential that the product is manufactured with exceptional care.

Energy Absorption Pads

These are specially designed pads which are made from high density closed-cell polymer foam with energy absorbing inserts. They are designed to protect the body from trauma by absorbing the force of impact and dispersing it. They can be exceptionally useful after serious trauma incidents and allow the body to heal without further damage being done. They are designed to be worn on any part of the body. They are breathable and have a relatively good degree of flexibility.

Alginate Dressings

This is a natural dressing for wounds made from seaweed. They are placed on wounds which are weeping heavily and the alginate will absorb up to twenty times its size. This makes them very effective at treating a wide variety of wounds. They come in a variety of forms, from rope form to wafer thin sheets; this ensures they can be used in almost any application.