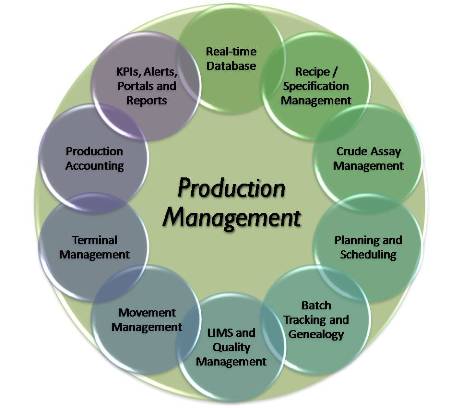

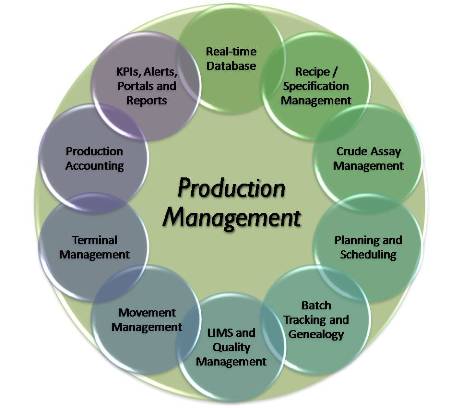

Production management involves the job of coordinating and controlling the activities required to manufacture a product. Production planning and its control are the main functions of production management.

Production planning involves designing of

Production facility · Process of various stages of production

Standards applicable to the production

Job or production lot · Data-flow

Schedule of production and maintenance

The control part of the production management involves effective control of

Quality

Inventory

Cost

Process

Through production planning and control, the company should achieve the following:

Production of goods and services of the right quality, right quantity, at the right time and at the minimum cost.

Improvement in the productivity and efficiency

Full or optimum utilization of available production capacity

Bring together the 6M’s i.e. men, money, machines, materials, methods and markets to bring products to the market more quickly, to ensure customer satisfaction and to maintain its market share.

Production Planning

Production planning requires creation of production capacity, which may include setting up plants, equipment and other supporting infrastructure.

Plant Layout

The layout of the plant plays a very vital role in overall production management. Hence, careful attention should be given in designing a layout of the plant and the placement of various interdependent elements within it. Our future needs and growth plans must also be considered while designing the layout of the plan. The material flow of our production process must be the basis of the layout design. It should allow for some changes, if time, space and priority permit.

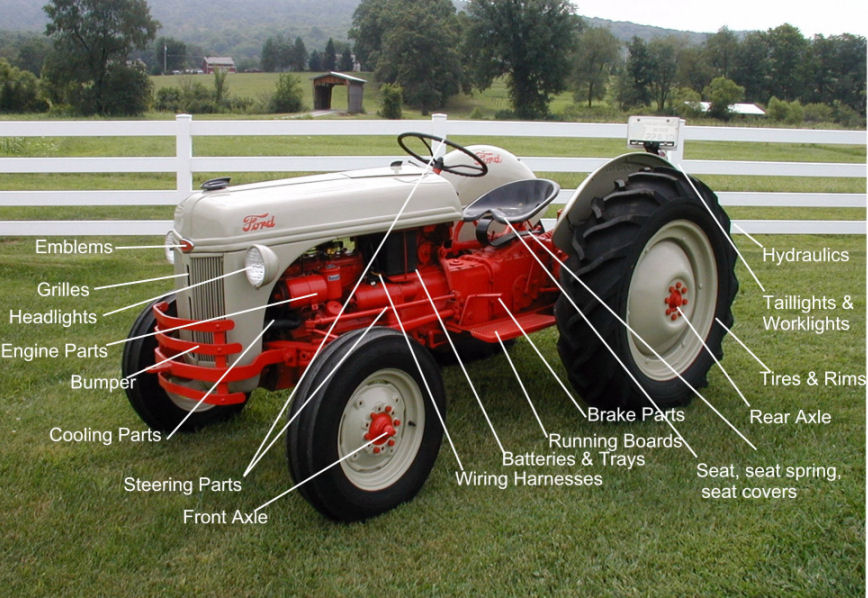

Equipment

The equipment must be chosen as per the requirements of our product quality, quantity and specifications. We must choose the equipment with the right productivity, efficiency and reliability standards. Consider the need for and costs of maintenance of the equipment. Check for health and safety issues in the operations of the equipment. Also consider the environmental issues (Waste and noise, air, water etc. pollution)

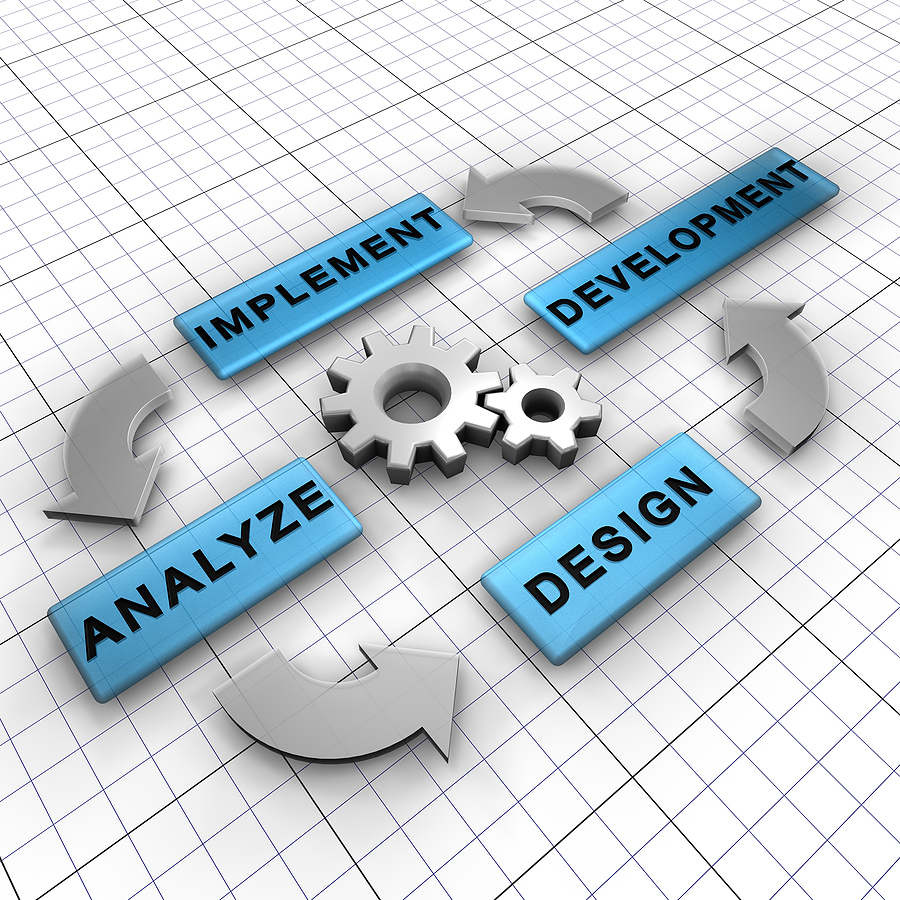

Process Design

Entire production activity is a series of processes. Starting from raw material to the production of finished product, there is a large number of intermediate processes which take place in a production facility. Each such intermediary process leading to finished product must be predefined. All these processes must be standardized to ensure reliability,

predictability and measurability of the production activity. So, each process must be designed carefully. The organized compilation of all the processes within a company forms the Operations Manual of the company.

Learn more about the Production management only at LSBF.